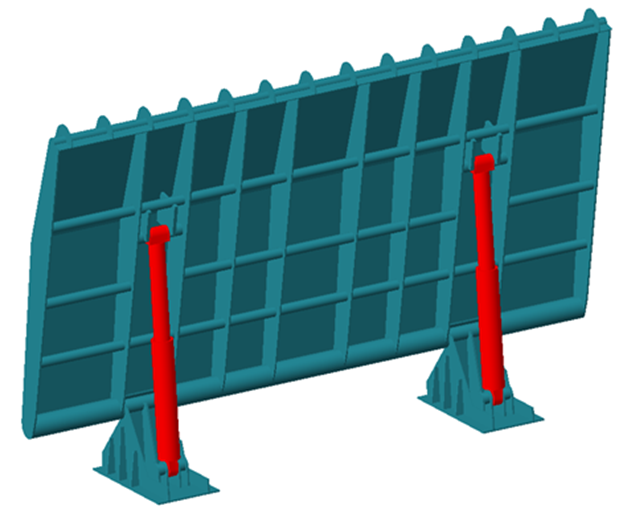

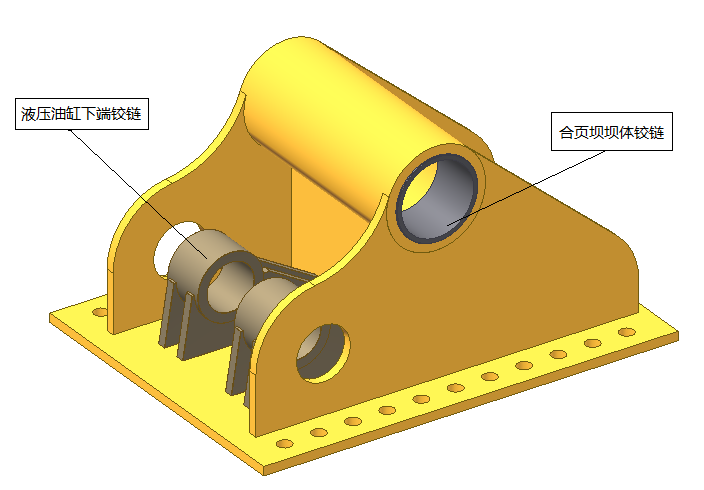

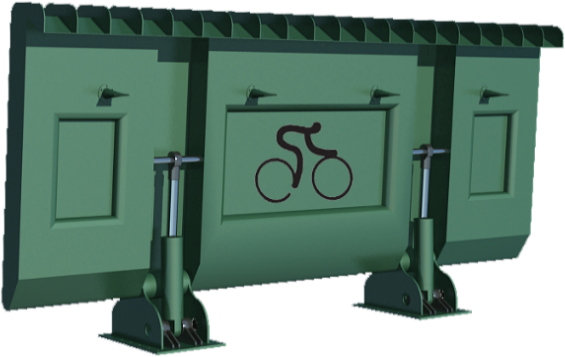

In the design process of the hydraulic elevator dam, the stability principle of the hydraulic three hinge point structure is fully utilized to optimize the design of the three hinge points. The upper hinge point, lower hinge point, and hinge dam bottom axis of the hydraulic cylinder are connected to a pre embedded steel plate in a hinged manner, so that the hydraulic cylinder, gate body, and bottom shaft hinge seat form an overall spatial force system through the foundation connecting plate. From the beginning to the end of the movement, they are always reflected in a triangular manner, and the oil cylinder supports the dam surface at a small angle. The direction of the dam surface and oil cylinder collapse is consistent. The structural design is novel, safe and reliable.

The bottom hinge support is the foundation of the hinge dam, which directly affects the stability of the integral hydraulic elevator dam, ensures its motion trajectory and accuracy requirements, and enables the hinge dam to fully play its due function during operation.

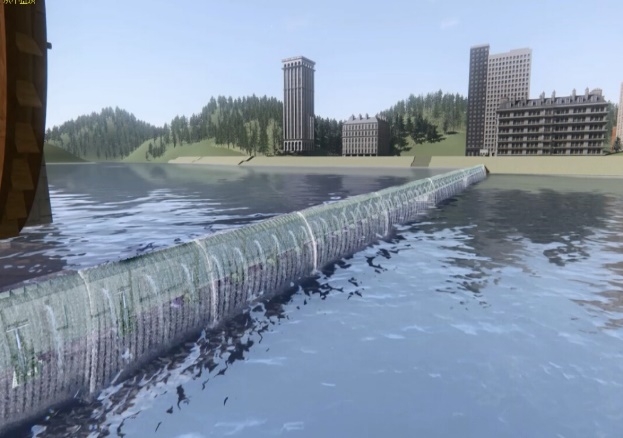

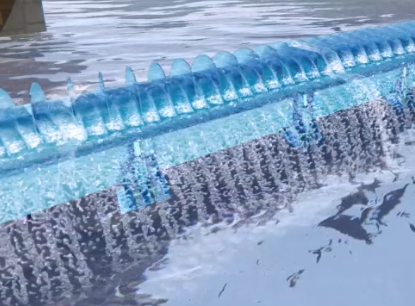

The dam crest is designed with exquisite water carrying components, which not only enhances the beauty of the dam body and the scenery of the waterfall, but also cleverly and effectively avoids the direct impact and corrosion of water on the hydraulic cylinder body during the overflow of the dam crest, reducing the possibility of hydraulic cylinder being impacted by water kinetic energy, erosion, and corrosion, and greatly improving the service life of hydraulic components.

Capable of controlling single or multiple gate bodies, with flexible operation; It can achieve water retaining adjustment at any height of the gate body and has strong flood discharge capacity. The lifting time of a single gate body is 1m/min, and through the unpowered lowering system, the entire line of gate body lowering can be adjusted at a variable speed from 30s to 30min, meeting the emergency lowering needs during flood periods. It is particularly suitable for areas with abundant rainfall, mountainous areas with rapid flood fluctuations, and urban river channels.

The winter non-deicing and deicing technology is another innovative point of hydraulic elevator dam. For the first time, the development concept of "enemy advance, enemy retreat, and self-advance" is integrated into the electrical and hydraulic control system of hydraulic elevator dam. Based on the characteristics of ice pressure growth, the overpressure relief timing is determined to achieve gate body retreat; then, through the electro-hydraulic system to lift and reset the dam, complete the ice breaking action.

The lowering speed of the hydraulic elevator dam can be adjusted from 30s to 30min according to the engineering characteristics. The maximum release speed and adjustment amplitude far exceed other similar dam types, greatly improving the safe flood discharge function of the hinge dam under unpowered and extremely harsh weather conditions. This technology is particularly suitable for urban rivers with rapid flood fluctuations and remote mountainous areas with power shortages. This technology has formed an integrated technology for variable speed and unpowered dam lowering under multiple scenarios, including power conditions, backup power supply, manned and unmanned duty, to meet various emergency flood discharge needs.

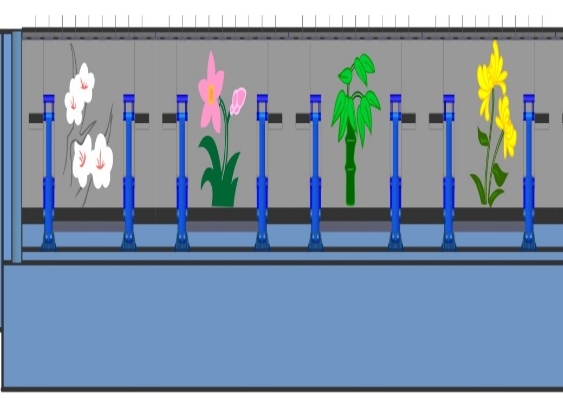

The design concept of the hydraulic elevator dam is unique, and the low center of gravity support form ensures the neatness and aesthetics of the hinge dam panel to a greater extent. At the same time, different colors, patterns, and slogans can be sprayed. The gate top flow device can not only form a beautiful waterfall, but also reduce vibration, protect the cylinder, and improve the overall aesthetics of the project, adding cultural and entertainment functions.

The hydraulic elevator dam can achieve both local PLC control and remote control

In order to closely follow the national call and respond to the national policy of "smart water conservancy", the hinge dam is used as a carrier to collect basic information and monitoring data information of the river and basin where the hydraulic elevator dam is located, providing data support for the construction of three-level water conservancy and river data.

The collected data mainly includes external perception data and internal perception data:

(1) External perception data is mainly collected through the organic combination of temperature sensors, rain gauges, water level gauges, ultrasonic flow meters, water quality samplers, camera equipment, and other collection devices with low head water gate projects, to collect on-site temperature information, rainfall information, water quality information (5 major indicators: BOD, COD, ammonia nitrogen, total phosphorus, SS), water level information, simulated flow information, video information External real-time perception data information such as GPS positioning information;

(2) Internal perception data mainly focuses on the collection of data related to the operation and maintenance of low head sluice gates, including gate bodies, hydraulic systems, oil cylinders, electrical control systems, and other related data.

The hydraulic elevator dam adopts a freestanding panel design, and a single panel can be operated independently. There is no need to install a trash rack upstream. When there are floating objects in the upstream, the single dam surface can be adjusted slightly, and the floating objects can pass smoothly. When the dam surface is stuck by branches and plastic bags, the coordination between a single dam surface or two dam surfaces can be adjusted based on the number and position of floating objects. At the same time, the floating objects can be washed away by the action of water flow. Even if there are small stones stuck between the two dam bodies, they can be adjusted multiple times by repeatedly adjusting the angle of the two dam surfaces, causing the stones to fall off.