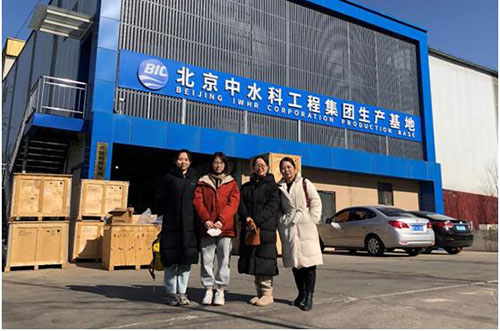

On January 31, 2023, the manager Dou led all the staff of second Sales Department to visit Beijing IWHR Corporation Production Base. The workshop area of Beijing IWHR Corporation Production base is 15,000 square meters, and the welding and manufacturing capacity of structural parts is 1,000 tons per month. The production base has many years of experiences in the manufacturing, installation, commissioning, maintenance, overhaul of non-standard equipment and lifting equipment, the ability to undertake turnkey projects, engineers with European standard certification qualification, welding workers with European standard welding certificate and flaw detection technicians with the flaw detection certificate of the Ministry of Railways.

Engineer Wang, the design department, led everyone to the production base for a visit. He introduced the production process of hydraulic elevator dam and the functions of various machine tools in the production base. Engineer Wang introduced to us that the base shaft sleeve and hinge shaft sleeve are processed by boring machine and lathes. Boring machines are generally used to process large diameter holes and end faces, while the function of lathes is to process rotating surfaces of different sizes and shapes; the bottom pipe and bottom pipe of hydraulic elevator dam are cut by sawing machines. Sawing machine is used to cut materials; CNC cut machines can cut plates of different shapes and thicknesses, mainly processing vertical plates, bottom vertical plates, etc; the edge milling machine is a welding auxiliary equipment of beveling the steel plate before welding. In addition, Engineer Wang added the processing of dam also requires welding operations for welding various types of structural parts. Finally, after processing and welding, abrasive blasting shall be used to achieve the roughness treatment of the gate. Then the gate shall be subject to anti-corrosion treatment by adopting the anti-corrosion method of hot galvanizing and sealing paint.

After this field visit to the production base, the sales department was more familiar with and understood the entire production and manufacturing process of the gate.