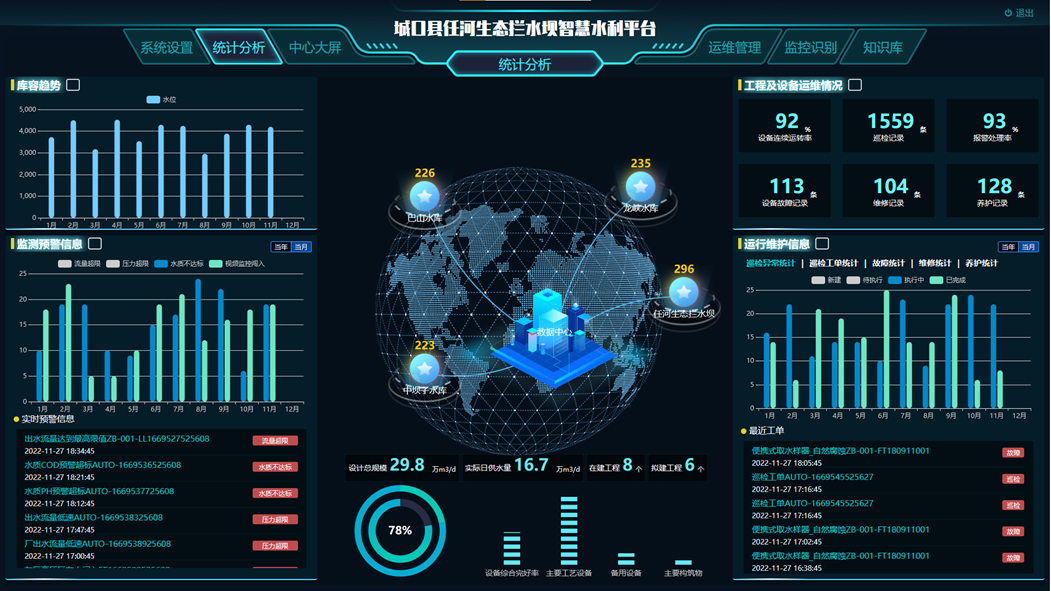

In order to actively respond to smart water conservancy and accelerate the construction of smart water conservancy, BIC has built the company's first digital twin water conservancy wisdom platform based on the current project in Chongqing, and the construction work is in full swing. The platform takes the water conservancy projects of five hydraulic Elevator dam stations as the unit, the spatial and temporal data as the base, and the

dynamic perception core, and builds a digital mapping intelligent monitoring unified information platform for the whole process of intelligent operation of water conservancy projects in digital space.

1. Integrated unified monitoring platform to realize unified management;

2. Global real-time dynamic perception to improve monitoring efficiency;

3. Simulation of visual dynamic effect;

4. Real-time alarm voice broadcast.

System mainly in engineering safety monitoring system, hydraulic Elevator dam monitoring system, video monitoring system as the main source of information, with communication transmission network for information transmission channel, with data resource management platform and application support platform for information storage, management carrier, with wisdom application system for application carrier, with web pages, mobile terminal application for information release and human-computer interaction carrier.

The data of hydraulic Elevator dam(internal) include: power line incoming voltage and three-phase current, the opening and closing of hydraulic station equipment, motor running current and speed, pump station outlet pressure, each hydraulic pipeline pressure, tank level, hydraulic oil temperature, hydraulic oil cleanliness, dam opening signal, threshold warning, fault alarm, etc.

The operation (external) data of the surrounding equipment of the hydraulic Elevator dam and related water conservancy data include: the operation situation of the surrounding equipment of the hydraulic hydraulic Elevator dam (light condition, etc.), river water level, river flow rate, river flow, etc. Management personnel inspect GPS positioning track and problem upload, asset management, personnel records, maintenance records, etc.

In addition, the BIC hydraulic Elevator dam has realized digital information, can be remote online monitoring, but also mobile APP real-time monitoring. At the same time, the mobile terminal operation application is added in the process of building the platform, which can optimize the display interface and operation mode on the basis of the desktop end to facilitate the operation.

Maintenance task: the dispatcher issues the work order for maintenance problems, and the maintenance personnel can take orders, handle the work order, report the work order, and record the materials used for maintenance.

Inspection task: for the periodic or temporary inspection task issued by the dispatcher, the inspection personnel shall inspect the inspection scope or route required by the work order, and report the inspection equipment situation;

Problem report: if the inspection personnel or maintenance personnel find problems in the process of work, they can work at the station problem. After the dispatcher sees the reported problems, they can arrange the maintenance personnel to repair in time.

The digital twin in water conservancy is to construct a virtual world with the same real physical river basin or unit on the computer, accurately simulate all activities in water conservancy management in the real world, realize the advanced simulation and deduction of all kinds of water conservancy management behaviors, and support the intelligent decision of water conservancy. At present, digital twin technology is widely used in river basin flood control, water resources management and allocation, water conservancy project construction and operation management, river and lake management and other aspects.